XNX XNX Honeywell Analytics 4 Universal Gas Transmitter

The XNX Universal Gas Transmitter from Honeywell Analytics is an advanced and flexible gas detection system capable of identifying a wide variety of gases, including flammable, toxic, and oxygen deficiency hazards. This safety solution reliably monitors hazardous environments to safeguard infrastructure, assets, and most importantly, human lives across various industries like oil and gas, chemicals, fire detection, etc.

Key Features of the Xnx Xnx universal transmitter

Gas Detection

Sensor technology

alarm systems

real -time monitoring

user-friendly interface

compliance and standards

About XNX Honeywell Universal Gas Transmitter

The XNX Universal Gas Transmitter from Honeywell Analytics is an advanced and flexible gas detection system capable of identifying a wide variety of gases, including flammable, toxic, oxygen enrichment and oxygen deficiency hazards. This safety solution reliably monitors hazardous environments to safeguard infrastructure, assets, and most importantly, human lives across various industries like oil and gas, chemicals, fire detection, etc.

In this article, we will look at the vital details around the XNX gas transmitter, including its unmatched detection capabilities, flexible configurations, ease of use, global certifications, and more that make Honeywell’s XNX a preferred choice for reliable and efficient gas hazard monitoring.

Honeywell Analytics – Overview

As a pioneer in gas detection technology for over 50 years, Honeywell Analytics, a division of the Honeywell conglomerate, offers specialized gas detectors, systems, and solutions tailored to the safety needs of diverse industries.

With innovation focused on preventing accidents related to toxic and combustible gases or oxygen depletion, Honeywell Analytics strives to ensure the protection of human life and valuable assets across the oil and gas, petrochemicals, chemicals, manufacturing, metals, and mining sectors globally.

Benefits and Features

Honeywell Analytics’ knowledge and expertise as pioneers in gas detection translates into distinct advantages offered by their XNX universal gas transmitter system:

Flexible Configurations

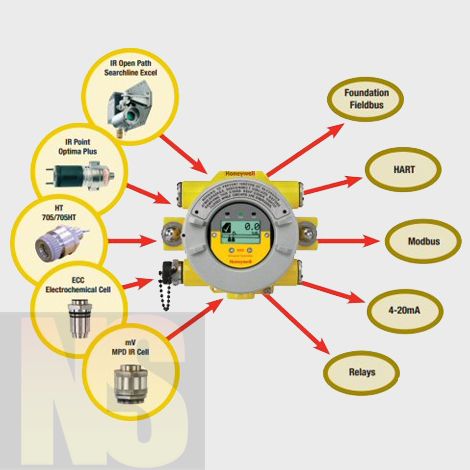

The XNX system is highly modular and can integrate up to 16 sensors measuring 4 gases each, all managed via one controller. This multi-sensor capacity allows cost savings and minimal footprint.

There are plug-and-play sensor spots and card slots to seamlessly integrate gas sensors, dry contacts, communication interfaces like Modbus, relays, and more.

Multi-gas Detection

With support for electrochemical, catalytic bead, infrared, and other sensor technologies, XNX provides accurate gas readings.

The measurement range spans from 0-100% LFL for combustibles or down to PPM levels for toxins like CO, and H2S. This allows using one system for diverse applications.

Rugged and Reliable

The XNX gas transmitter conforms to IP66, NEMA Type 4X standards making it suitable for harsh environments in industries like oil and gas, chemicals, etc.

It has UL/cUL, ATEX, IECEx, and INMETRO zone certifications for guaranteed safety and permissions for explosive applications. Further, the system is compliant with failure safety standards like SIL 2.

Enhanced Diagnostics

Unique cell verification features like Surecell and Reflex eliminate false alarms. The self-test routines further enhance reliability.

Digital sensing technology enables predictive diagnostics for managing sensor life and calibration intervals. This minimizes downtimes.

Simple Maintenance

The XNX gas transmitter facilitates one-person maintenance without shutting processes. The modular plug-and-play sensors and cells reduce downtime allowing hot-swappable sensor replacement.

XNX XNX Honeywell Analytics Universal Gas Transmitter Applications

This high-performing modular gas detector provides comprehensive protection across diverse industries:

Oil and Gas Industry

The XNX is commonly used in oil refineries, offshore platforms, pipelines, and other oil & gas facilities to detect and monitor flammable hydrocarbons like methane as well as toxic gases like H2S or CO. Maintaining gas safety is crucial in this industry.

Chemical Processing Plants

Chemical and petrochemical plants extensively use the XNX to identify gas leakages and continued exposure risks from chemicals or byproducts that may be toxic, combustible, or reduce oxygen levels. Tight gas detection ensures conformance to process safety protocols.

Food and Beverage

The XNX monitors oxygen levels and combustible gases in food packaging plants, beverage production facilities, distilleries, dairies, etc. to prevent food spoilage or contamination and reduce fire hazards.

Pharmaceutical Industry

Toxic, asphyxiating, or combustible gases may be generated during drug manufacturing, making gas detection imperative. The XNX enables compliance with cGMP and other pharma safety regulations.

Fire and Suppression Systems

The XNX can supplement conventional smoke detectors in fire alarm monitoring applications by detecting flammable gas buil-dups early. It can also be integrated with automated fire suppression systems involving inert gas releases.

HVAC Systems

Air quality is monitored via the XNX in the heating, ventilation, and air-conditioning systems of large commercial or residential buildings for keeping carbon monoxide, VOCs, and refrigerant gases below harmful limits.

Water Treatment Facilities

Gases like chlorine, sulfur dioxide, or ozone used for water purification are monitored by the XNX to protect personnel and optimize dosing while ensuring treated water safety specs.

Power Generation

Power plants deploy the XNX gas transmitter to monitor flammable gases near electrical equipment and detect carbon monoxide and other byproducts from generators or boilers.

Transportation Sector

Onboard ships, ferries, and offshore vessels, the XNX helps monitor engine room or cargo hold atmospheres for keeping hydrocarbon and other vapor levels safe.

XNX XNX Honeywell Analytics Universal Gas Transmitter Technology

The XNX transmitter utilizes different innovative gas sensing technologies along with specialized personality boards to detect a wide variety of hazardous gases reliably.

Catalytic Bead Technology

The Catalytic Bead Technology offers fast response times to combustible and flammable gases. It can work with bead sensors from legacy Honeywell models for easy replacement when required. A dedicated mV personality board optimizes the performance of this technology.

Electrochemical (EC) Cells

The Electrochemical (EC) Cells technology enhances the precision of detecting toxic gases even down to the ppm level concentrations. It employs a patented ‘Reflex’ cell system to verify faults or issues with the cells.

The ‘Surecell’ EC cells are durable even in hot and humid conditions commonly encountered in industrial worksites. Furthermore, the electrochemical board auto-recognizes plug-and-play sensors to simplify configuration procedures.

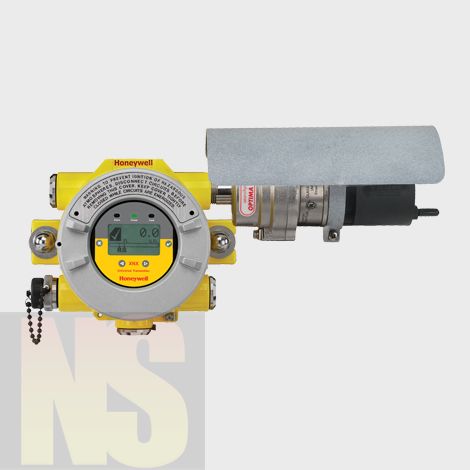

Infrared (IR) Detection

The Infrared (IR) Detection method supports the monitoring of IR-active gases like CO2 by analyzing their absorption spectra. Point IR configurations utilize heated optics resistant to contamination for reliable functionality.

Importantly, IR detection is immune to catalytic poisons which can impact other competing gas-sensing techniques.

Specifications

Below are the specifications you should match with your needs:

Construction Materials

The standard XNX transmitter housing utilizes painted lightweight aluminum (LM25 grade) for corrosion resistance. For more demanding environments, stainless steel (SS316) construction with an exterior protective coating can be chosen as well.

Operating Temperature Range

Depending on the internal sensors equipped, the XNX transmitter will deliver reliable performance in temperatures from -40°C to +65°C (-40°F to +150°F). The operating range varies across sensor types.

Humidity Tolerance

The XNX transmitter and its internal components are designed to handle relative humidity levels between 20% and 90% without risk of condensation building up. Exposure to humidity outside this range may impact device functionality and should be avoided.

Global Safety Certifications and Compliance

With rigorous testing and adherence to standards, XNX delivers fail-safe operations you can count on:

| Certificate/Standard | Significance |

| ATEX/IECEx | For use in explosive atmospheres |

| SIL2 Performance | High safety integrity against faults |

| UL/CSA | Certified for US and Canada |

| CE Marking | Meets EU safety, health standards |

So whether it’s keeping offshore oil rigs explosion-proof or preventing asphyxiation risks in breweries, the versatile and technologically advanced XNX Universal Gas Transmitter has your back.

Choosing the Right XNX Gas Detector

Since the XNX comes in different configurations, the following factors must be evaluated to select the appropriate system for your needs:

Identify Gases to be Detected

Determine all hazard scenarios and the specific gases that require monitoring. For example, methane and nonane detection would warrant combustible catalytic bead sensors.

Define Concentration Monitoring Ranges

Concentration monitoring ranges for each gas should align with exposure limits defined by safety regulations. Typical electrochemical toxic gas sensors in the XNX detect gases from 0-100 ppm levels. Catalytic sensors range from 0-100% LEL for combustibles.

Environmental Analysis

Consider temperature, humidity, dust levels, and potential contaminants to determine optimal sensor technology. For example, electrochemical sensors excel in dusty environments, unlike optical detectors. Corrosive atmospheres might warrant stainless steel enclosures.

Certification Requirements

Industry-specific certifications like UL or marine approvals must be met by the system. Zone rating approval is also essential for installation in classified hazardous locations alongside flammable gases.

Connectivity Considerations

Evaluate existing and required connectivity for central monitoring and control systems. Add communication modules like HART, Modbus, or relays accordingly.

Budget Constraints

Modular plug-and-play sensors provide great flexibility in optimizing investments through customization. Extra I/O slots also allow for future sensor additions.

Why Choose XNX XNX Honeywell Analytics Gas Detectors?

Engineered with exceptional capabilities backed by Honeywell Analytics’ decades of industry expertise, here are compelling reasons to choose xnx xnx universal transmitters:

- The multi-sensor platform detects a broad spectrum of gases reliably

- Fail-safe operation with continuous autonomous self-diagnostics

- Future-proof modular design with plug-and-play sensor replacement

- Interference-resistant infrared technology immune to sensor poisoning

- Seamlessly integrates with control and safety systems through flexible I/O options

- Complies with global standards like ATEX, UL, IECEx, SIL2

- Lower lifecycle costs through flexible field upgrade-able configurations

- Honeywell Analytics’ global product support service coverage

- The xnx xnx offers versatile advantages that maximize safety, lower TCO, ensure compliance and provide complete peace of mind across installations prone to hazardous gas leaks and explosions.

XNX XNX Honeywell Analytics Universal Gas Transmitter – FAQs

Conclusion

The XNX Universal Gas Transmitter from Honeywell Analytics offers unmatched flexibility, safety, and performance for gas detection across industrial sites. Its modular design, field-proven sensor technologies, and hazard resistance certifications make it suitable for virtually any application. With its intuitive UI and diagnostics capabilities, the XNX also minimizes downtime and maintenance costs compared to traditional gas detectors. For comprehensive protection from gas hazards, the XNX is an ideal solution.